While the installer is home Wiring inside the walls, the homeowner is carefully checking the CCC certification mark on the wires at the building materials market—the first line of defense for home safety.

The quality of home wiring directly impacts home safety. This primarily focuses on two key indicators: conductor resistance and insulation thickness.

Choosing the right wiring not only ensures smooth power supply but also protects the safety of the entire family.

01 Choosing Cable Specifications to Match the Load Capacity of Home Appliances

Thicker wires aren’t always better, but critical circuits must be thick enough. The basis for choosing home wiring specifications is the power capacity of the appliances the circuit can handle. The basic principle is to use different specifications of wire for different power areas and appliances with different power ratings.

For lighting circuits, 1.5 square millimeter copper core wire is recommended. It can safely carry up to 2200 watts of power, fully meeting the needs of low-power devices such as lamps and fans.

For ordinary socket circuits, 2.5 square millimeter wire is needed, with a safe load of approximately 4500 watts, capable of supporting small to medium-sized appliances such as televisions and computers. These circuits are typically protected with 16-amp circuit breakers.

High-power appliances must have dedicated wiring. Air conditioners, instant water heaters, and other high-power equipment must use dedicated 4 square millimeter (4 sq mm) circuits, with a current carrying capacity of up to 7000 watts. It is recommended that the outdoor unit of a central air conditioning system be upgraded to 6 sq mm.

Special attention should be paid to the kitchen area, where appliances such as microwave ovens, rice cookers, and built-in steam ovens have high power consumption. Even if the power of a single appliance does not exceed the limit, it is recommended to set up a separate circuit to avoid overloading the circuit due to multiple appliances operating simultaneously.

02 Choosing High-Quality Wires: Mastering the “Seven Checks” Selection Method

When purchasing wires, mastering the “seven checks” techniques can significantly reduce the risk of buying inferior products.

Checking the label is the first step. Qualified wire products should have complete label information, including the manufacturer’s name, address, model specifications, applicable standards, and voltage rating.

Most importantly, look for the CCC certification mark, which is China’s mandatory product certification.

Checking the insulation quality is crucial. You can cut a small section of the insulation layer and observe its cross-section for air bubbles. High-quality insulation should be of uniform thickness and tightly bonded to the wire core. Inferior wires will exhibit an “off-center” phenomenon, meaning the insulation layer is not centered, and the severely off-center side is prone to leakage.

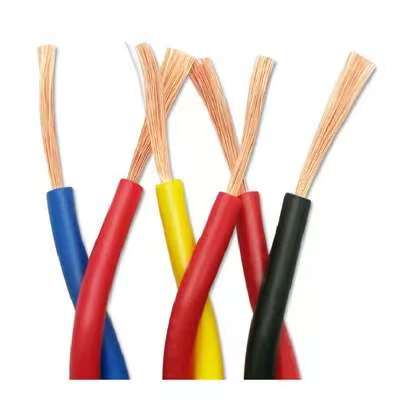

Examining the copper wire is crucial for judging wire quality. High-quality copper wire is purplish-red, lustrous, and highly flexible, remaining intact even after repeated bending. Inferior copper wire may be purplish-red with a blackish tinge, or whitish-yellow, rough, dull, and easily broken when folded.

Checking the applicable standards is the basis for judging product compliance. Wire and cable products should comply with currently valid standards, such as the GB/T 5023 series and GB/T 5013 series.

Do not purchase products that indicate an obsolete standard.

It is worth noting that the national standard project “General Safety Requirements for Wires and Cables” is currently under development, which will establish a unified mandatory safety standard for wire and cable products.

Checking the packaging, weight, and flammability are also important methods. Standard electrical wires have intact packaging, clear labels, meet weight standards, and have a certain degree of flame retardancy in their insulation layer; they should self-extinguish after being removed from an open flame.

03 Characteristics and Applicable Scenarios of Different Types of Electrical Wires

Commonly used electrical wires in home decoration mainly fall into two categories: BV wire and BVR wire, each with its own characteristics.

BV wire (single-strand hard wire) is the most commonly used home decoration wire. It consists of a single copper wire, has high rigidity and strong tensile strength, and is relatively inexpensive, but it is not easy to return to its original shape after bending, making conduit installation slightly more difficult.

BVR wire (multi-strand soft wire) is made of multiple thin copper wires twisted together. It has good flexibility and is easy to install in conduits, especially advantageous in wiring scenarios with many bends, but it is relatively more expensive.

From a safety perspective, flame-retardant wires are the first choice for home decoration. Flame-retardant wires can prevent the spread of flames when exposed to fire, preventing the fire from escalating.With increasingly stringent safety standards, low-smoke halogen-free wires are also becoming increasingly popular. These wires do not produce toxic halogen gases when burning, and have low smoke density, which is beneficial for people to escape in case of fire. 05 Budgeting and Quantity Planning for Electrical Wire Purchases

04 Budgeting and Quantity Planning for Electrical Wire Purchases

The price of home electrical wires is affected by factors such as copper prices, brand, and specifications. Generally, high-quality brand wires are more expensive per meter. Although the initial investment in high-quality wires is higher, considering their longer lifespan and better safety, it is a worthwhile investment in the long run.

Electrical wire usage planning needs to be estimated based on the house area and layout. For example, for a house under 90 square meters, approximately 3 rolls of 1.5 square millimeter wire, 5 rolls of 2.5 square millimeter wire, and 2 rolls of 4 square millimeter wire are typically needed.

Larger houses such as villas require approximately 50% more wire.

In the total home renovation budget, electrical wire typically accounts for 1%-3% of the total renovation cost. Although this percentage is small, it is the part that should not be skimped on, because repair costs are extremely high if problems occur.

Regarding purchasing channels, it is recommended to choose reputable building materials markets, brand stores, or officially authorized e-commerce platforms, and avoid purchasing from unlicensed small shops. Always request a formal invoice or receipt when purchasing electrical wiring, as proof for after-sales service and rights protection.

The quality of home wiring directly affects family safety. From the initial material selection to installation, every step is crucial.

After installation, the electrical system must undergo rigorous testing before being put into use. Testers use megohmmeters to check the insulation resistance of each section of the wires to ensure the values meet safety standards.

Choosing the right home wiring is a matter of integrity hidden within the walls. Guangxi Dahua Qunshan Cable sincerely safeguards your home. Inquiries are welcome!